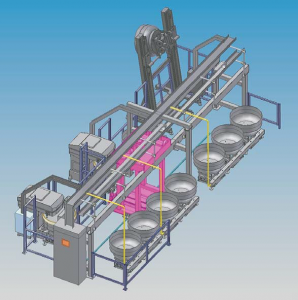

FULL MIXING PHASE INTEGRATED SOLUTION

FULL MIXING PHASE INTEGRATED SOLUTION

A transfer trolley that moves on modular rails raised from floor on supporting columns and serves the Working stations.

Higher productivity and qualitative homogeneous products due to the automatic control of the mixers, the movement of the trolleys, dumpers and portioning hoppers.

HIGH PRODUCTIVE POTENTIALS – FLEXIBILITY – MODULARITY

For some productions, the quantity of dough that a compartment can handle can be as much as 7500-9000 kg/h and beyond.

MIXER designers in collaboration with the customer’s technicians can customise the necessary plant for all mixing needs:

BY DEFINING the number and the type of Working stations (dough mixing, rest, lifting);

BY CALIBRATING the features and functions of the mixers, lifters and the portioning hoppers.

CLEANING AND MAINTENANCE EASE

Particular care is taken in the design to make the cleaning and maintenance of all the components of the plant simple.

FULL MIXING PHASE INTEGRATED SOLUTION

FULL MIXING PHASE INTEGRATED SOLUTION