FS 2000

Description It is a 10-line machine able to work 20.000 pieces per hour; in the best working conditions it can even achieve an output of 24.000 pieces per hour. Conceived to automatically fill and seal dairy products and adaptable to every kind of liquid and doughy products, it is suitable for medium and large […]

F 1800

DESCRIPTION The Fill Seal 1800 is a filling/sealing machine equipped with an automatic turntable of 6 positions, suitable for production up to 1800 pieces per hour. The machine is designed for packaging liquid and doughy products, such as yogurt, cheese, milk, margarine, butter, jam, honey, sauces, soups, etc… in pre-formed containers made of PS, PET, […]

FS 4L

Description The FILL SEAL 4L is an in line filling/sealing machine working on 4 rows. It is a completely automatic machine able to satisfy high productions (up to 10000 pieces per hour). The machine can run containers made of PS, PP, PET, aluminium, coupled cardboard, etc …. The volumetric dosing system allows to package a […]

SB PLUS 420

Description The Ilpra SEAL BOX PLUS 420 is an automatic line able to thermoseal 4 containers per cycle and it is composed as follows: – Mechanical in feed conveyor – 8 positions star wheel, mechanically driven – Sealing and cutting station – Mechanical ejection conveyor – Control panel – Safety protections – Dimensions of the […]

SB 280

Description The Ilpra SEAL BOX 280 is an automatic line able to thermoseal 4 containers per cycle and it is composed as follows: – Mechanical in feed conveyor – 8 positions star wheel, mechanically driven – Sealing and cutting station – Mechanical ejection conveyor – Control panel – Safety protections – Dimensions of the container: […]

SB 160

Description The Seal Box 160 model is a thermosealing machine with a 4-station starwheel. It is conceived to run non-destackable containers made of plastic, glass, metal …. It is suitable to meet customer’s needs in different fields such as cosmetics, pharmaceutics, foodstuff. This model is ideal for small and medium sized productions (up to 1500 […]

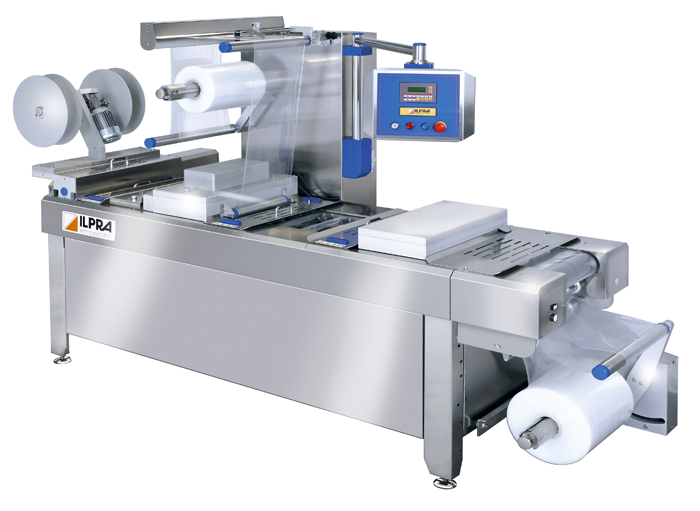

FORMPACK F1

Description The Formpack F1 model is an in-line thermoforming machine with an innovative design, completely made of AISI 304 stainless steel and anodized aluminum with IP 65 protection class. The Formpack F1 is suitable for medium productions. This model, thanks to high versatility, can be applied in food, industrial and medical field. • The machine […]

FORMPACK F4/F5

Description The Formpack models F4 and F5 are thermoforming machines able to satisfy both medium and high production requirements, depending on the different kinds of customization. The main features of both models are as follows: -They can be used with a wide variety of thermoform films, including flexible, rigid and foamed materials. All standard sealing […]

EASYFORM

Description The EASYFORM model is a very compact in line thermoforming machine. Only 3 meter long, this machine features at best the principles of a new technology conceived to meet the different requirements of customers in industrial, food and medical sectors. Its features are the following: • Versatility: the machine can thermoform both flexible and […]

|

|

||||||

| DESCRIPTION : ILPRA was founded in 1955. The company plays a primary role in the market of food, cosmetics and medical packaging. Up till now ILPRA has installed over 14,000 machines worldwide. The packaging is the core of a business formula oriented to a entirely internal production. ILPRA operates in 130 countries worldwide, with technologically advanced innovative solutions able to guarantee maximum flexibility and high process automation. The ILPRA Group also covers all aspects of Packaging thanks to 10 institutional partners 1. Domestic production ILPRA has focused its care on customers’ satisfaction. We are always actively engaged in a direct and constructive dialogue with our customers. To achieve this aim ILPRA chooses domestic production to provide a single source that can offer the widest warranties. http://www.ilpra.com/index.php/en/company-profile/about-us |

|||||||