A C HORN & CO Archive

Designed with the operator in mind, all of these systems are fully adjustable for operator comfort, minimizing labor requirements normally associated with case packing. Our Smart Pak conveyor accepts the bags from the packaging machine, gently conveying them to the pack-off table or individual case. The loose pack adaptation allows the packer to easily convert to the flipper option, which automatically counts and distributes bags at speeds up to 140 bags per minute.

Designed with the operator in mind, all of these systems are fully adjustable for operator comfort, minimizing labor requirements normally associated with case packing. Our Smart Pak conveyor accepts the bags from the packaging machine, gently conveying them to the pack-off table or individual case. The loose pack adaptation allows the packer to easily convert to the flipper option, which automatically counts and distributes bags at speeds up to 140 bags per minute.

A.C. Horn & Co. is known for providing solutions to the packaging industry. The Packoff Conveyor is another of our packaging solutions. Designed with the operator in mind, all of these systems are fully adjustable for operator comfort, thus minimizing labor requirements normally associated with case packing. Our Packoff Conveyor accepts the bags from the packaging machine, gently conveying them to the Rotary Table for packing.

A.C. Horn & Co. is known for providing solutions to the packaging industry. The Packoff Conveyor is another of our packaging solutions. Designed with the operator in mind, all of these systems are fully adjustable for operator comfort, thus minimizing labor requirements normally associated with case packing. Our Packoff Conveyor accepts the bags from the packaging machine, gently conveying them to the Rotary Table for packing.

The only collator on the market specifically designed for today’s 140+ bag per minute vertical form, fill and seal machines. This machine gently catches, then conveys the bags into our proprietary twin packing rows, allowing packers to work independently. Efficient and ergonomically friendly, the Double Lane Collator stacks and counts bags, minimizing musculoskeletal stresses and labor requirements.

The only collator on the market specifically designed for today’s 140+ bag per minute vertical form, fill and seal machines. This machine gently catches, then conveys the bags into our proprietary twin packing rows, allowing packers to work independently. Efficient and ergonomically friendly, the Double Lane Collator stacks and counts bags, minimizing musculoskeletal stresses and labor requirements.

Increase your production capacity and consistency while lowering your operating costs with A.C. Horn & Company’s Single Lane Collator. Designed with the operator in mind, these systems are manufactured for operator comfort, thus minimizing labor requirements and reducing the stressesnormally associated with case packing. The Single Lane Collator accepts bags from the packaging machine, gently conveying them into a collating conveyor. The collator then aligns the bags for easy packing. The collator can also count and group the bags to your case configuration

Increase your production capacity and consistency while lowering your operating costs with A.C. Horn & Company’s Single Lane Collator. Designed with the operator in mind, these systems are manufactured for operator comfort, thus minimizing labor requirements and reducing the stressesnormally associated with case packing. The Single Lane Collator accepts bags from the packaging machine, gently conveying them into a collating conveyor. The collator then aligns the bags for easy packing. The collator can also count and group the bags to your case configuration

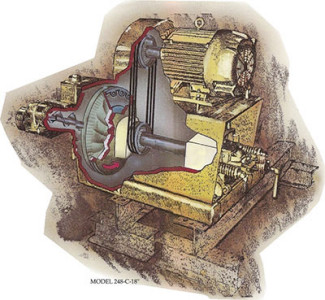

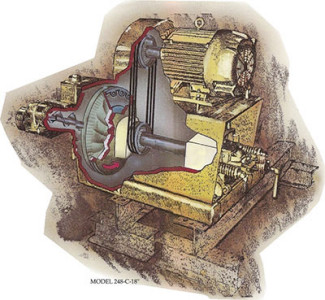

This highly versatile, single-disk attrition mill can be used in all kinds of production and laboratory applications of both industrial and food products. Painstakingly made to exacting tolerances, this 8-inch mill can pulverize, grind, granulate, comminute, crack, fluff and texturize a wide variety of items with a precision unmatched by other mills. The legendary Bauer 148 Mill has long been recommended by the U.S. Department of Agriculture for the preparation of cottonseed samples (this sampling requires Bauer Plate No. 8503 and a mill speed of 3600 RPM). This mill is also endorsed by the American Oil Chemist Society and is widely used by its members. Its dependable performance makes it the mill of choice for a wide number of agricultural experimental stations, university laboratories and industrial research and production departments. It also gives superior performance as a production machine as well, producing 1,000 to 2,000 pounds of smooth, easy-to-spread peanut butter, perfectly blending stabilizer, salt, dextrose, etc., to produce a mix of creamy smooth consistency.

This highly versatile, single-disk attrition mill can be used in all kinds of production and laboratory applications of both industrial and food products. Painstakingly made to exacting tolerances, this 8-inch mill can pulverize, grind, granulate, comminute, crack, fluff and texturize a wide variety of items with a precision unmatched by other mills. The legendary Bauer 148 Mill has long been recommended by the U.S. Department of Agriculture for the preparation of cottonseed samples (this sampling requires Bauer Plate No. 8503 and a mill speed of 3600 RPM). This mill is also endorsed by the American Oil Chemist Society and is widely used by its members. Its dependable performance makes it the mill of choice for a wide number of agricultural experimental stations, university laboratories and industrial research and production departments. It also gives superior performance as a production machine as well, producing 1,000 to 2,000 pounds of smooth, easy-to-spread peanut butter, perfectly blending stabilizer, salt, dextrose, etc., to produce a mix of creamy smooth consistency.

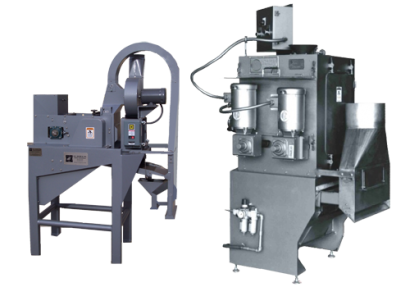

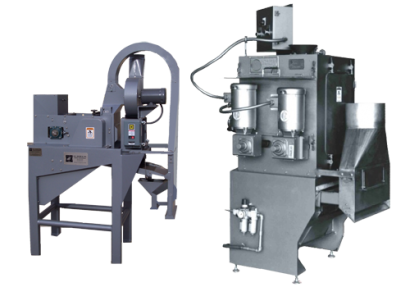

Our Granulator is the only machine that is exclusively engineered to granulate nuts- all types of them. Instead of crushing the product as other multipurpose machines do, it is uniquely designed to comminute nuts into defined, sharp-edged granules with minimum production of fines. The granulator is flexible; you can choose from eight knife spacings ranging between 1/16″ to 1/4″. It’s efficient and it’s clean, with most contact parts made of stainless steel. It is available in three models: Capacities from 600 to 2,400 pounds per hour.

Our Granulator is the only machine that is exclusively engineered to granulate nuts- all types of them. Instead of crushing the product as other multipurpose machines do, it is uniquely designed to comminute nuts into defined, sharp-edged granules with minimum production of fines. The granulator is flexible; you can choose from eight knife spacings ranging between 1/16″ to 1/4″. It’s efficient and it’s clean, with most contact parts made of stainless steel. It is available in three models: Capacities from 600 to 2,400 pounds per hour.

We confidently guarantee our larger-capacity whole nut blancher makes a better-looking nut than any other blancher in existence. Unlike blanchers which use abrasive rolls, our patented Model 346-C uses rubber elements to produce the highest quality, best-looking nuts with the least amount of shrinkage – no scratches anywhere. And true to its name, it gently blanches 2000 pounds per hour of peanuts for snack foods, confectionery candy and similar products.

We confidently guarantee our larger-capacity whole nut blancher makes a better-looking nut than any other blancher in existence. Unlike blanchers which use abrasive rolls, our patented Model 346-C uses rubber elements to produce the highest quality, best-looking nuts with the least amount of shrinkage – no scratches anywhere. And true to its name, it gently blanches 2000 pounds per hour of peanuts for snack foods, confectionery candy and similar products.

For the highest quality in blanched peanuts, choose the blanchers that are No. 1 in the world: A.C. Horn & Co.’s 341-B Split Nut Blancher or the VB-5000 Split Nut Blancher. They remove the skins & hearts from dried or fully roaster peanuts for the smoothes, cleanest nuts possible – absolutely no traces of worn edges anywhere. You can choose between up to 2,000 pounds per hour or 5,000 lbs per hour of roasted or dried peanuts. The product can be blanched free of meal & with less shrinkage than any other blancher on the market. Operation is simple & reliable. The blanchers first split the nuts & remove the skins; the hearts are then removed from the halves. Screening separated the halves from the hearts, and aspiration totally removes the skins from the process. Dependable features like a trouble-free adjustable feed hopper & a dual-aspiration system allow you to process nuts for peanut butter, candy and similar products with maximum efficiency.

For the highest quality in blanched peanuts, choose the blanchers that are No. 1 in the world: A.C. Horn & Co.’s 341-B Split Nut Blancher or the VB-5000 Split Nut Blancher. They remove the skins & hearts from dried or fully roaster peanuts for the smoothes, cleanest nuts possible – absolutely no traces of worn edges anywhere. You can choose between up to 2,000 pounds per hour or 5,000 lbs per hour of roasted or dried peanuts. The product can be blanched free of meal & with less shrinkage than any other blancher on the market. Operation is simple & reliable. The blanchers first split the nuts & remove the skins; the hearts are then removed from the halves. Screening separated the halves from the hearts, and aspiration totally removes the skins from the process. Dependable features like a trouble-free adjustable feed hopper & a dual-aspiration system allow you to process nuts for peanut butter, candy and similar products with maximum efficiency.

Telford Turbo-Flo Roaster

Telford Turbo-Flo Roaster

Putting quality into the entire process is exactly what we’ve done with our new Telford Turbo-Flo Roaster. Designed to meet virtually every roasting and drying need, A.C Horn & Company has used state of the art processing technology to ensure even, consistent roasting and drying. This results in ton after ton of consistent product. The Telford Turbo-Flo also provides maximum fuel efficiency with the lowest possible operating cost. These ovens are chosen by food processors throughout the world when roasting or drying peanuts, almonds, filberts, sunflower seeds or other similar materials.

A.C. Horn & Co. is known for providing solutions to the packaging industry. The Packoff Conveyor is another of our packaging solutions. Designed with the operator in mind, all of these systems are fully adjustable for operator comfort, thus minimizing labor requirements normally associated with case packing. Our Packoff Conveyor accepts the bags from the packaging machine, gently conveying them to the Rotary Table for packing.

A.C. Horn & Co. is known for providing solutions to the packaging industry. The Packoff Conveyor is another of our packaging solutions. Designed with the operator in mind, all of these systems are fully adjustable for operator comfort, thus minimizing labor requirements normally associated with case packing. Our Packoff Conveyor accepts the bags from the packaging machine, gently conveying them to the Rotary Table for packing. The only collator on the market specifically designed for today’s 140+ bag per minute vertical form, fill and seal machines. This machine gently catches, then conveys the bags into our proprietary twin packing rows, allowing packers to work independently. Efficient and ergonomically friendly, the Double Lane Collator stacks and counts bags, minimizing musculoskeletal stresses and labor requirements.

The only collator on the market specifically designed for today’s 140+ bag per minute vertical form, fill and seal machines. This machine gently catches, then conveys the bags into our proprietary twin packing rows, allowing packers to work independently. Efficient and ergonomically friendly, the Double Lane Collator stacks and counts bags, minimizing musculoskeletal stresses and labor requirements. Increase your production capacity and consistency while lowering your operating costs with A.C. Horn & Company’s Single Lane Collator. Designed with the operator in mind, these systems are manufactured for operator comfort, thus minimizing labor requirements and reducing the stressesnormally associated with case packing. The Single Lane Collator accepts bags from the packaging machine, gently conveying them into a collating conveyor. The collator then aligns the bags for easy packing. The collator can also count and group the bags to your case configuration

Increase your production capacity and consistency while lowering your operating costs with A.C. Horn & Company’s Single Lane Collator. Designed with the operator in mind, these systems are manufactured for operator comfort, thus minimizing labor requirements and reducing the stressesnormally associated with case packing. The Single Lane Collator accepts bags from the packaging machine, gently conveying them into a collating conveyor. The collator then aligns the bags for easy packing. The collator can also count and group the bags to your case configuration This highly versatile, single-disk attrition mill can be used in all kinds of production and laboratory applications of both industrial and food products. Painstakingly made to exacting tolerances, this 8-inch mill can pulverize, grind, granulate, comminute, crack, fluff and texturize a wide variety of items with a precision unmatched by other mills. The legendary Bauer 148 Mill has long been recommended by the U.S. Department of Agriculture for the preparation of cottonseed samples (this sampling requires Bauer Plate No. 8503 and a mill speed of 3600 RPM). This mill is also endorsed by the American Oil Chemist Society and is widely used by its members. Its dependable performance makes it the mill of choice for a wide number of agricultural experimental stations, university laboratories and industrial research and production departments. It also gives superior performance as a production machine as well, producing 1,000 to 2,000 pounds of smooth, easy-to-spread peanut butter, perfectly blending stabilizer, salt, dextrose, etc., to produce a mix of creamy smooth consistency.

This highly versatile, single-disk attrition mill can be used in all kinds of production and laboratory applications of both industrial and food products. Painstakingly made to exacting tolerances, this 8-inch mill can pulverize, grind, granulate, comminute, crack, fluff and texturize a wide variety of items with a precision unmatched by other mills. The legendary Bauer 148 Mill has long been recommended by the U.S. Department of Agriculture for the preparation of cottonseed samples (this sampling requires Bauer Plate No. 8503 and a mill speed of 3600 RPM). This mill is also endorsed by the American Oil Chemist Society and is widely used by its members. Its dependable performance makes it the mill of choice for a wide number of agricultural experimental stations, university laboratories and industrial research and production departments. It also gives superior performance as a production machine as well, producing 1,000 to 2,000 pounds of smooth, easy-to-spread peanut butter, perfectly blending stabilizer, salt, dextrose, etc., to produce a mix of creamy smooth consistency. Our Granulator is the only machine that is exclusively engineered to granulate nuts- all types of them. Instead of crushing the product as other multipurpose machines do, it is uniquely designed to comminute nuts into defined, sharp-edged granules with minimum production of fines. The granulator is flexible; you can choose from eight knife spacings ranging between 1/16″ to 1/4″. It’s efficient and it’s clean, with most contact parts made of stainless steel. It is available in three models: Capacities from 600 to 2,400 pounds per hour.

Our Granulator is the only machine that is exclusively engineered to granulate nuts- all types of them. Instead of crushing the product as other multipurpose machines do, it is uniquely designed to comminute nuts into defined, sharp-edged granules with minimum production of fines. The granulator is flexible; you can choose from eight knife spacings ranging between 1/16″ to 1/4″. It’s efficient and it’s clean, with most contact parts made of stainless steel. It is available in three models: Capacities from 600 to 2,400 pounds per hour. We confidently guarantee our larger-capacity whole nut blancher makes a better-looking nut than any other blancher in existence. Unlike blanchers which use abrasive rolls, our patented Model 346-C uses rubber elements to produce the highest quality, best-looking nuts with the least amount of shrinkage – no scratches anywhere. And true to its name, it gently blanches 2000 pounds per hour of peanuts for snack foods, confectionery candy and similar products.

We confidently guarantee our larger-capacity whole nut blancher makes a better-looking nut than any other blancher in existence. Unlike blanchers which use abrasive rolls, our patented Model 346-C uses rubber elements to produce the highest quality, best-looking nuts with the least amount of shrinkage – no scratches anywhere. And true to its name, it gently blanches 2000 pounds per hour of peanuts for snack foods, confectionery candy and similar products. For the highest quality in blanched peanuts, choose the blanchers that are No. 1 in the world: A.C. Horn & Co.’s 341-B Split Nut Blancher or the VB-5000 Split Nut Blancher. They remove the skins & hearts from dried or fully roaster peanuts for the smoothes, cleanest nuts possible – absolutely no traces of worn edges anywhere. You can choose between up to 2,000 pounds per hour or 5,000 lbs per hour of roasted or dried peanuts. The product can be blanched free of meal & with less shrinkage than any other blancher on the market. Operation is simple & reliable. The blanchers first split the nuts & remove the skins; the hearts are then removed from the halves. Screening separated the halves from the hearts, and aspiration totally removes the skins from the process. Dependable features like a trouble-free adjustable feed hopper & a dual-aspiration system allow you to process nuts for peanut butter, candy and similar products with maximum efficiency.

For the highest quality in blanched peanuts, choose the blanchers that are No. 1 in the world: A.C. Horn & Co.’s 341-B Split Nut Blancher or the VB-5000 Split Nut Blancher. They remove the skins & hearts from dried or fully roaster peanuts for the smoothes, cleanest nuts possible – absolutely no traces of worn edges anywhere. You can choose between up to 2,000 pounds per hour or 5,000 lbs per hour of roasted or dried peanuts. The product can be blanched free of meal & with less shrinkage than any other blancher on the market. Operation is simple & reliable. The blanchers first split the nuts & remove the skins; the hearts are then removed from the halves. Screening separated the halves from the hearts, and aspiration totally removes the skins from the process. Dependable features like a trouble-free adjustable feed hopper & a dual-aspiration system allow you to process nuts for peanut butter, candy and similar products with maximum efficiency. Telford Turbo-Flo Roaster

Telford Turbo-Flo Roaster