CORN MASA MILLS

Our Stoneless Masa mill produces 2,500 – 6000 lbs/hr of finished masa. The mill is simple to use, dependable and robust. This unit does not use grinding stones & does not require shim stock to establish parallelism between the stationary disc and the rotating disc. The plate life of our mill is rated at approximately […]

320 POPCORN COOKER/COATER

Putting quality into the entire process: The 320 Cooker/Coater has the A.C. Horn & Co. quality and more, all built into its unique single process design. Ingredients are added when the pre-programmed temperature set points are reached and the alarm is activated. The cooking/coating process continues until the coated corn is ready! This Cooker/Coater is […]

M205 COOKER-COATER SYSTEM

Putting quality into the entire process is our ultimate goal at A.C. Horn & Co. Making perfect caramel corn is the goal for the Perfection Series Cooker/Coaters. These precision built machines are engineered to give you decades of superior performance and durability. Caramel Corn, Peanut Brittle and other caramel coated products can be manufactured at […]

CONTINUOUS DRY POPPERS

In 1962 Manley manufactured its first Uniflow Design popcorn popper. Since that time, and through many improvements, A.C. Horn/Cantrell International has been a leader in high capacity, continuous popcorn production systems. We believe there is no higher quality popping system manufactured or designed on the market today. The Platinum Series offers the latest PLC controls […]

AUTOMATIC POPCORN BALL MACHINE

The Model M563 Popcorn ball maker from A.C. Horn & Co. has been upgraded with a PLC and servo motor drive.Speeds up to 80 balls per minute. Frame, hopper and catchpans are constructed of stainless steel for easy sanitation. Hopper comes complete with internal heaters and product agitators.Forming cups are food grade UHMW Polyethylene.Optional forms […]

PUFFERS MACHINE

In 1962 Manley manufactured its first Uniflow Design popcorn popper. Since that time, and through many improvements, A.C. Horn/Cantrell International has been a leader in high capacity, continuous popcorn production systems. We believe there is no higher quality popping system manufactured or designed on the market today. The Platinum Series offers the latest PLC controls […]

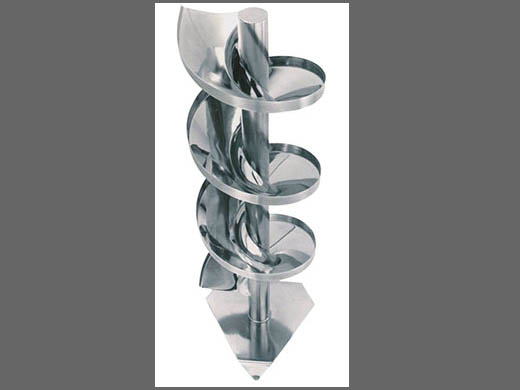

SPIRAL CHUTE

Decrease your broken product and improve your product appearance! Sound impossible? Not with A.C. Horn & Company’s Winchester Smooth-Flo Chute. The unique design of the patented Winchester Smooth-flow Chute has useful applications anywhere gentle product handling is required and space is limited. Originally developed to over-come problems inherent in standard commercial spiral chutes, its simple […]

RETRACTABLE SPIRAL

Reduce product damage and improve product appearance with our Winchester Retractable Smooth-Flow Spiral Chute! This unique device was designed primarily to gently fill bulk totes, never dropping product more than a few inches as it retracts out of the tote, filling as it rises. We start by positioning a tote and lowering the Smooth-Flo Chute […]

BATCH ROASTERS

The Ray-o-matic and Radiant-Ray Roasters are the top choice for a company seeking a low-cost, high-quality roaster . These roasters assure uniform roasting with maximum flavor development. You will get the best-looking, best-tasting nuts – in your choice of 2,000 pounds per hour or 1,000 lbs/hr, fully automatic Ray-o-matic or manual Radiant-Ray models. Uniform color […]

|

|

||||||||

| DESCRIPTION : Since 1907 A. C. Horn & Co. has achieved a reputation of Excellence and Integrity in Precision Metal Fabrication and Manufacturing of Food Processing/Packaging Systems. This includes a wide array of equipment: Batch Roasters and Continuous Roasters, Butter Mills (Peanut Butter, Almond Butter, Cashew Butter, Sesame Butter, plus other nut butters), Split Nut Blanchers and Whole Nut Blanchers, Granulators, Corn Masa Mills. We design and manufacture Popcorn Poppers, Puffers, Caramel Coaters, and Kettle Corn Poppers.We also offer Plant Layout and Machine Design for your specific application, in the processing room and the packaging room. All of this is designed and manufactured in our state of the art 65,000 square foot ft. plant. We are equipped with CNC punching and laser cutting, CNC machining, forming equipment, welding, finishing, and powder coating. This variety of equipment allows us to consider many opportunities for custom metal fabrication. http://www.achornco.com/ |

|||||||||