ILPRA Archive

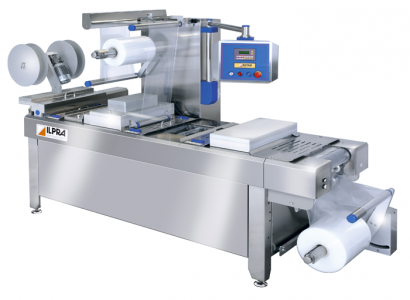

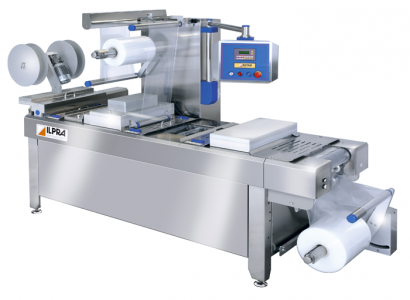

Description

Description

The model 400 is suitable for sealing different kinds of trays ( plastic, aluminum, coupled cardboard) by means of heatsealable/compatible film coming from a reel or pre cut lids. The feeding of trays to the sealing area and the consequent ejection of the same area manually performed (by means of a tray carrier), while the film unwinding/rewinding and sealing/cutting are automatically performed.

It is also possible to obtain the vacuum sealed packaging by means of the Vacuum/Gas kit.

The machine is completely made of stainless steel and anodized aluminum and is perfectly suitable for working in wet environments.

Cleaning and maintenance are easy and quick.

This model is able to carry out about 500 cycles/hour by working without vacuum/gas facilities. The usable sealing area is 350×270 mm and it is possible to use moulds of up 2 impressions , that increase the output.

Adjusting the machine to another tray size is easy and quick.

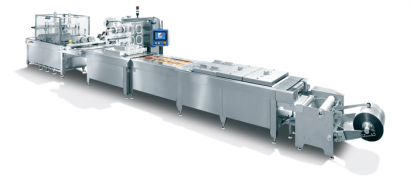

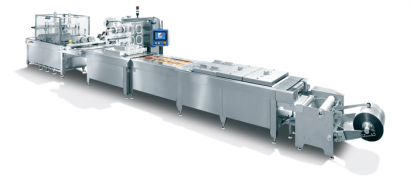

Description

Description

The FOODPACK SPEEDY DUE is an in-line machine whose structural principles meet the hygienic and safety requirements of the standards in force.

Thanks to the materials used for its manufacturing, the FP SPEEDY DUE machine is suitable for working in wet and/or aggressive environments. All the electric connections have got IP 65 class protection.

The feeding conveyor has got 5 free steps where it is possible to place denesting systems, fillers and other options.

Available options:

• Automatic tray destacking unit;

• Several coding systems for the expiry/production date;

• Printed top web system for the right placement of the printed film on the tray;

• Dosing systems;

• Automatic snap-on lids device;

• Moulds and modification kit in order to work 3 or 4 trays per cycle;

• Motorized ejection conveyor.

Description

Description

The FOODPACK 1403 is a completely automatic tray sealer designed for high productions.

The mechanical movement of this model results in a very high working precision.

Because of the wide sealing area the FP 1403 is equipped with an air/oil booster which gives off a pressure of 7 tons to grant a perfect sealing.

The machine is available in two versions: for sealing only and for vacuum packaging or vacuum / gas packaging.

The machine is primarily constructed in stainless steel and has IP 65 class protection making the 1403 the ideal machine to work in aggressive environments, such as dairy products or sauce and brine packaging.

Complete access to the machine is easily gained through the front and rear doors of the machine, that can be easily lifted by a vertical moving.

Cleaning and maintenance operations become very easy and quick.

The tooling changeover is both efficient and quick, thanks to a simple mechanical system.

The new film unwind system allows for high precision in normal working and precise placement when working with pre-printed materials.

The PLC can store up to 30 working programs that are easily uploaded onto the display screen.

The machine can be customized with several options such as printed top web, snap on lids, coding stations, de-nesting and filling systems.

Description

Description

The EASYFORM model is a very compact in line thermoforming machine. Only 3 meter long, this machine features at best the principles of a new technology conceived to meet the different requirements of customers in industrial, food and medical sectors. Its features are the following:

• Versatility: the machine can thermoform both flexible and rigid material. It is available in two versions: Easyform N for sealing only and Easyform VG for vacuum packaging and vacuum/gas packaging.

• Friendly use: it is suitable for different productions thanks to the very easy size change. It is the ideal also for customer at their first packaging experience.

• Standard configuration : it is possible to choose a wide combination of sizes available in stock, thus reducing the delivery term at competitive prices.

• Hygiene: completely constructed of stainless steel and anodized aluminum with IP 65 protection class it can be easily washed and be placed in very humid and aggressive working environment.

• Custom tailored: a wide range of options makes the machine suitable for different working requirements.

Description

Description

The Formpack models F4 and F5 are thermoforming machines able to satisfy both medium and high production requirements, depending on the different kinds of customization.

The main features of both models are as follows:

-They can be used with a wide variety of thermoform films, including flexible, rigid and foamed materials. All standard sealing materials such as plastic, medical paper and tyvec can be used.

– The F4 and F5 machines are available in both seal-only format and vacuum-gas format for producing vacuum, MAP and skin packs.

– The machines can be customized regards the length of frame, the mould motion, the thermoforming system, the loading area, the number and type of cutting stations.

– Both models are suitable for working in damp, aggressive environments as the chassis, all protection covers and bearings are made from stainless steel and the machine is IP65 rated.

– No external lubrication is required.

– Colour touch-screen with error diagnostic function. It can also display the electric and pneumatic schemes and some basic instructions.

– Changeover with quick release

– Other options include shape cutting, printed top web, coding units, in-line printing and labelling systems, in-line dosing/filling systems.

Description

Description

The Formpack F1 model is an in-line thermoforming machine with an innovative design, completely made of AISI 304 stainless steel and anodized aluminum with IP 65 protection class. The Formpack F1 is suitable for medium productions.

This model, thanks to high versatility, can be applied in food, industrial and medical field.

• The machine can work with both flexible and rigid materials.

• The Formpack F1 is available in two versions: N for sealing only and VG for vacuum packaging, vacuum/ gas and skinpackaging.

• The machine can be completely washed down and operated damp environments.

• The changeover is quick and easy.

• The supplied brushless motor enables high precision and speed.

• This machine can be customized with several options such as Print Registration, coding units, dosing systems, slicers, in-line flexographic printer, as well as obtain the “Europe hole“.

Description

Description

The Seal Box 160 model is a thermosealing machine with a 4-station starwheel. It is conceived to run non-destackable containers made of plastic, glass, metal …. It is suitable to meet customer’s needs in different fields such as cosmetics, pharmaceutics, foodstuff.

This model is ideal for small and medium sized productions (up to 1500 pieces/hours), combining the highest quality with low price.

Constructed of stainless steel, the SB 160 is built to withstand aggressive and damp environment (IP 65 class protection).Cleaning and maintenance operations are easy and fast.

The control panel is friendly use and can store all machine functions.The filler and sealing head are driven pneumatically, while all other stations are mechanical.The machine can be customized on request.Several accessories such as coding systems, printed top web,capping are available.

Description

Description

The Ilpra SEAL BOX 280 is an automatic line able to thermoseal 4 containers per cycle and it is composed as follows:

– Mechanical in feed conveyor

– 8 positions star wheel, mechanically driven

– Sealing and cutting station

– Mechanical ejection conveyor

– Control panel

– Safety protections

– Dimensions of the container: Max diam. mm. 120, Max depth mm 220

All the SEAL BOX machines ( SEAL BOX 280 included) are in stainless steel and anodized aluminum and are suitable for working in wet environment.

This machine is electronically controlled and thermoregulated ; the sealing group motion is realized pneumatically and these functions are driven by a control panel.

Cleaning and maintenance are easy and quick.

Description

Description

The Ilpra SEAL BOX PLUS 420 is an automatic line able to thermoseal 4 containers per cycle and it is composed as follows:

– Mechanical in feed conveyor

– 8 positions star wheel, mechanically driven

– Sealing and cutting station

– Mechanical ejection conveyor

– Control panel

– Safety protections

– Dimensions of the container: Max diam. mm. 65, Max depth mm 220.

All the SEAL BOX machines ( SEAL BOX 420 PLUS included) are in stainless steel and anodized aluminum and are suitable for working in wet environment.

This machine is electronically controlled and thermoregulated ; the sealing group motion is realized pneumatically and these functions are driven by a control panel. Cleaning and maintenance are easy and quick.

Description

Description Description

Description Description

Description Description

Description Description

Description Description

Description Description

Description Description

Description Description

Description